First, you need to know that every digital camera (including digital night vision devices) has the main part that captures the light coming through the lens to form an image. This part is called a sensor. Mainly, a sensor is a solid device which captures the light and forms it into a digital image that you see in the other end on the screen. There are lots of different sensor types built in digital devices.

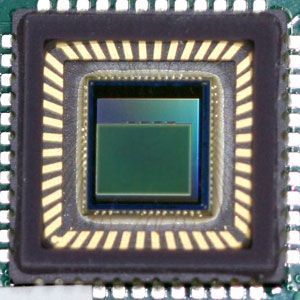

CMOS Sensor

The most commonly used sensor is CMOS (Complementary Metal-Oxide-Semiconductor). CMOS uses the latest technology which enables very high integration on the microchips with high performance and miniaturized integrated electronic circuits.

CCD sensor

CCD or charge-coupled device sensor was produced before CMOS sensors. Latest technology CCD image sensors are used in professional, medical and scientific devices where high-quality image data is needed. For devices, where you don’t need a high-quality image, such as professional digital cameras and so on, CMOS sensors are usually used. So digital night vision devices with CMOS sensors are cheaper then devices with CCD sensor, due to CMOS uses a newer and cheaper technology.

Thermal imaging sensors

Thermal imaging devices use special sensors or infrared (IR) detectors that detect Long Wavelength Infrared (LWIR) band from 7 μm – 14 μm. An IR sensor is the heart of any thermal imaging device. The Most common IR sensors (detectors) available today are sensors which are cooled or uncooled. These special IR sensors are built out of quite exotic and expensive materials such as sensing pixel array, IR ROIC (Infrared Readout Intergraded Circuit), vacuum package and back-end electronics.

Cooled IR sensors were developed in the 1950s for military application use. Disadvantages of this type of IR sensors is that they require additional accessories to obtain operating temperatures between -70 and -150 °C, what makes thermal imaging device bigger and heavier. These extra cooling accessories are also expensive, they use a lot of power and they require a cooling-down time process, which takes around 10 to 20 minutes to get the first image on a thermal imaging device. Mostly those thermal imaging devices are used in the military (mostly in military transport) because they need a higher performance technology that enables longer distance detection and don’t need a device that gives you instant-on image.

Uncooled IR sensors are commonly microbolometer based sensors, the development started in the 1990s. There are 2 most common types on the market – microbolometer made out of Vanadium Oxide (VOx) or Amorphous Silicon (ASi). A big advantage of uncooled IR sensors is that they are cheaper then cooled IR sensors and don’t need extra cooling-down accessories, what makes these thermal imaging devices portable, lightweight and they have low battery power consumption. They also provide an instant-on image, what means, you are able to see your image only in few seconds after you turn the device on (no cooling-down processes). The disadvantages of uncooled IR sensors are; they are less sensitive, have lower performance and speed of constant detection of the image then cooled IR sensors.

Vanadium Oxide (VOx) microbolometer (uncooled IR sensor) and Amorphous Silicon (ASi) microbolometer (uncooled IR sensor) are the two main types of microbolometers used today in thermal imaging devices. Both are designed to work in the same way (core technology of both is similar), but the main difference is of what material is the sensor built of.

Source: Pulsar (CMOS sensor)